Introduction

Since the beginning of this project, we both knew we wanted to work on something acoustically related, as this was the topic we were most comfortable with. Since we are both wind instrumentalists, we both related with the struggle of sometimes limiting our practice sessions due to possible noise complaints.

Motivation and Goals

Practice is crucial among all instrumentalists. However, a common problem we have is that trying to squeeze some extra practice can sometimes be met with noise complaints from household members and neighbors alike. This is especially true when practicing in rooms that were built without soundproofing considerations. To amend this problem, several companies have created attachments for some wind instruments that effectively reduces overall noise emitted from the instrument. However, no muting product is commercially available for the flute as of now.

In comparison to muting an instrument such as the trumpet, muting a flute is much more difficult. This is due to the fact that interfering with the mechanisms that output the actual timbre of the flute also influences the clarity of the notes [1]. Upon this realization, we decided that the best path to take was an external, yet portable solution. Thus, we conceived the idea to make a mini anechoic chamber that fits around our flute and flutist’s playing position. Our end goal is to basically verify that an implementation of this flute-mute concept is possible, and it could hopefully develop into a usable consumer product.

Constructing the Mute

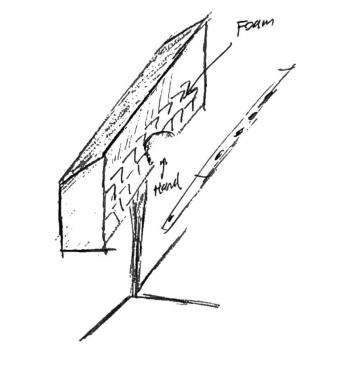

Concept art for mini anechoic flute chamber

Our plan for the mute began considering the ergonomics of the contraption first. As pictured in the concept art above, the mute will have an open face with enough clearance for the player’s head, while a carved out portion will allow the player’s left hand to enter and reach their flute. The insides were to be padded with melamine foam, a material that is easily obtainable and possess a decent sound absorption coefficient.[2] Importantly, the sound absorption coefficient was relatively constant over the entire frequency range of interest (200-5000 Hz) and actually increased as the frequency went higher, which was desirable.

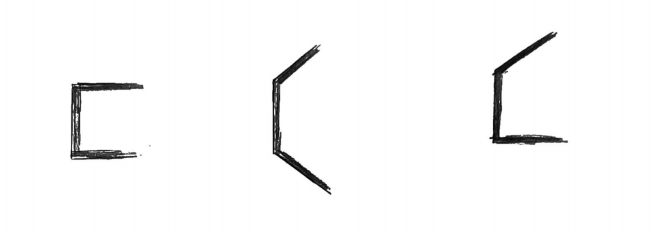

Final design

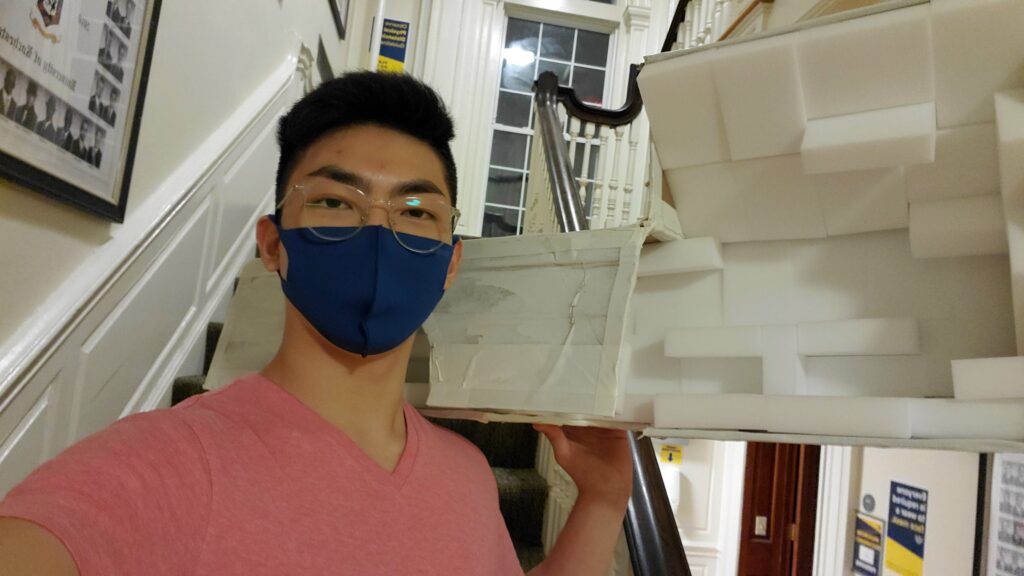

After tinkering with several ideas, we settled on the design illustrated above. The first third of the mute has a larger, trapezoidal cross-section to create clearance for the player’s head. The latter sections of the mute have been reduced to a square cross-section. This reduction was made to hopefully reduce any sound attenuation coming from the sound holes of the flute, where there isn’t much need for clearance other than for the player’s hands. When the cardboard and melamine foam became available, Jaewoo went to work with the shell construction and padding.

Finished flute mute

Measurement Methods

Eight Behringer ECM8000 measurement mics were used in a 3D array around the flutist. The vertical line represents the Z-Axis response, as measured by the higher and lower microphones, while the larger polar pattern represents the XY-Plane response, measured by the remaining six microphones.

Bibliography

[1] “The Structure of the Flute: How is the Sound Produced?” Yamaha. https://www.yamaha.com/en/musical_instrument_guide/flute/mechanism/mechanism002.html

[2] “Absorption Coefficients” Acoustic.ua. https://www.acoustic.ua/st/web_absorption_data_eng.pdf